BST GmbH

Booth number: C32

www.bst.elexis.group

About us

BST is a leading manufacturer of quality assurance measures for the web processing industries. With our range of measures, we competently cover all areas relevant to quality assurance. Customers who choose BST benefit from first-class products, extensive cross industry application know-how, and reliable service.

Address

Remusweg 1

33729 Bielefeld

Germany

E-mail: info@bst.group

Phone: +49 521 400700

Internet: www.bst.elexis.group

Tozkoparan Mah. General Ali Riza Gürcan Cd. Metropol Center A blok No:31 Kat:6 Ofis: 26

34173 Istanbul

Turkey

E-mail: bilgi@bst.group

Phone: +90 212 4891052

Internet: www.bst.elexis.group/tr/

Contact person:

Özgür Cetinkaya

Managing Director of BST Eltromat Istanbul Kontrol Sistemleri Ticaret Ltd. Şti

E-mail: Ozgur.Cetinkaya@bst.group

Phone: +90 212 4891052

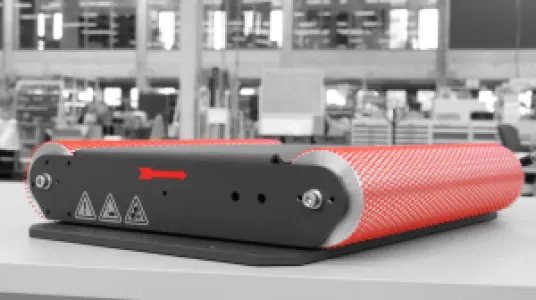

Web guiding systems

The basis for efficiency and quality in web-based production processes is precise and stable web guiding. The challenge is to take full advantage of machine speeds and simultaneously ensure that the material being processed is exactly at its intended position. BST web guiding can be used for a wide range of substrates and effectively minimize waste and downtime. At BST, we customize solutions to align with your production requirements. From web guiding devices and controllers to sensors and actuators, we provide comprehensive coverage for all your web guiding needs.

CLS CAM 200

CLS CAM 200 - Smaller. Smarter. Easier to use

The CLS CAM 200 sensor is the logical further development of the proven CLS PRO 600. The matrix camera sensor controls with high precision and according to print lines, print edges or web edges. As with its predecessor, operation is as intuitive as possible. Thanks to a completely revised menu structure, the user guidance can be adapted to the respective application and thus streamlined. The sensor provides clear feedback on the measurement status and also works reliably with critical materials, e.g. reflective surfaces, thanks to the switchable bright and dark field illumination.

The new BST Commander SMART COM 100 enables simultaneous operation of sensor and control unit for the first time. Your advantage: Fewer user interfaces and limited variety of parts, and therefore all relevant information at a glance.

TubeScan - Intelligent print inspection

TubeScan product series

For 100% print quality monitoring, web inspection systems are not suitable and must be combined with print inspection systems. The TubeScan product family (TubeScan digital strobe, TubeScan digital strobe XL, TubeScan eagle view) is your ideal and cost-efficient entry into 100% print inspection – especially in combination with the inspection workflow QLink, consisting of QLinkPress, QLinkEditor, QLinkRewinder and QLinkViewer.

POWERScope - High performance video technology for flawless print results

BST's POWERScope 5000 digital monitoring system is ideal for label printing and other narrow web applications. However, even when monitoring larger webs, the system delivers first-rate performance with maximum efficiency. POWERScope 5000 combines state-of-the-art technology with ease of use, while being perfectly suited to the needs of modern printing machines. The BST system uses a compact digital camera for excellent image quality and offers numerous innovative functions that are unique in the entry-level segment in web monitoring.